What is plastic extrusion?

- Share

- Issue Time

- Mar 5,2018

What is plastic extrusion?

What is plastic extrusion? In a basic technical definition, it is the transformation of solid plastic mass converted into a shape that can be used as produced or converted into usable products.

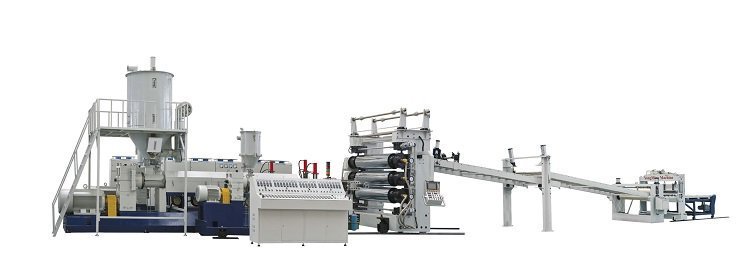

Plastic extrusion is used in the three primary processes of producing a plastic part – extrusion, injection molding and blow molding. There is a uniqueness to each primary process. Extrusion is continuous, injection molding is discontinuous and blow molding would also be considered continuous. Because of these differences, each process presents its own challenges but for this post we will focus on extrusion. Extrusion is a continuous process of converting a solid plastic mass, pellet or powder into a melted form where it is pushed through a die into a shape. This shape is then moved through various secondary operations where it is cooled then cut, coiled or experiences a variety of other possible operations. Extrusion can be broken into specific sub-processes which are sheet, blown or cast film, profile, pipe or pelletizing. Outputs from these processes include:

Plastic sheet turned into drinking cups or food storage containers

Films used for grocery bags or to protect our food from harmful contamination while increasing its shelf life

Plastic pipe to safely deliver water to our homes without the worry of lead contamination or to clad the sides of our homes for an aesthetically pleasing low maintenance look

Each sub-process is unique requiring different dies, post extrusion or downstream equipment to produce the desired product. Regardless of the process, each sub process has a single component in common, an extruder.

The extruder’s job is to transform the solid plastic mass or feed stock into a melted form. To do this are two core extruder technologies, single and twin screw. The single screw extruder is the most widely used technology for extrusion. It has the versatility to process a wide variety of polymer types and can be applied to all common extrusion processes. The twin screw extruder technology is broken down further to include counter-rotating and co-rotating. The counter-rotating twin screw extruder uses two screws which intermesh and rotate opposite to one another. The co-rotating twin uses two screws which intermesh and rotate in the same direction. Whether a single screw or twin they are used to accomplish a single purpose – to transform a solid mass into a melt. This transformation process is the beginning of the extrusion process and has an immense impact on the overall process. The extruder is often called the heart of the extrusion process. Taking this a step further, the extruder screw is frequently called the heart of the extruder. Why is the extruder screw the heart of the extruder or the extrusion process itself? Because if the extruder screw does not perform at an optimum level the rest of extrusion process will suffer. This is why the screw has been the most studied component of the extrusion process outside of polymer chemistry. In the future we will discuss the extruder and the screw and how they influence the extrusion process.