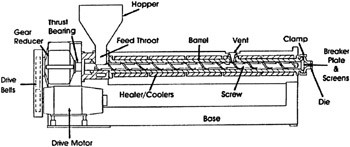

Single screw extrusion

- Share

- Issue Time

- Apr 19,2018

Single screw extrusion

Extrusion is a technology to convey materials which dates back far before the plastic era. It has been in use in the ceramics industry for ages. When we also include screws to transport water, the technology is thousands of years old.

For plastic processing, extrusion has been used from the start. First to convey PVC and polyethylene, later also for engineering plastics. However, screw modifications became necessary.

The length of a screw is expressed as the ratio between diameter and length.

For a 21 D screw with a diameter 3 cm, the active length is thus 63 cm.

Since the emergence of crystalline engineering plastics, the length of the screws had to be increased. A screw length of 24 D is quite common.

The geometry of screws can be varied. Widely used for extrusion applications are 3-zone screws and barrier screws.

3-zone screws consist of 3 zones:

Feed section

Compression section

Metering section

The feed section is the part of the screw where the unmolten polymer enters into the barrel. The rotating screw moves the material along the heated barrel where it starts to melt.

In the compression zone, gases like air and volatiles like moisture, are being removed. In the compression zone, the flight depth decreases and gases are pushed back into the direction of the hopper.

Finally, the material enters the metering section. In this section, pressure is generatedwhich enables the material to be conveyed into the shaping area, like feed block or film die.

The compression ratio of the screw is the ratio between the flight depth of the feed section and the ratio of the metering section.

Most screws have a flight helix that is equal to the diameter of the screw.

Feeding

To understand the mechanism of the conveying ability of the extruder screw, it is helpful to imagine a screw or bolt in a barrel. When the screw rotates any material between the screw surface and the barrel wall will be conveyed dependent upon the direction of rotation. Obviously, the extruder is designed to move the material from hopper to the front of the extruder.

Compression

Until the granules are molten, with every screw rotation, the material will be conveyed 1 speed. What has been conveyed is a mixture of roughly 50 % solids and 50 % air.

Without compression section, the molten material behaves like a foam. In the compression section, the volatiles are pushed back into the direction of the hopper.

The length of the compression section depends on the polymer to be extruded. The extreme example of PVC, the compression section comprised the full length of the screw. For crystalline polymers a very short compression section is recommended.

Metering

The molten and compressed polymer now enters the metering zone. The flight depth is less than in the feeding zone, but the flight depth is equal over its length.

The function of the metering section is to build-up pressure. The amount of pressure that can be build-up, depends on the length of the metering zone.

Mixing

All single screw extruders show some mixing effect, although very limited. For the proper dispersion of additives like stabilizers, antiblock agents, etc., mixing elements are being used.

There are various types of mixing sections, like Maddock, pineapple or pintype mixing elements.

Barrier screws

Another way of efficient mixing is using a barrier screw. Using this type of screw, the polymer is forced over the flights of the screw into a second channel.